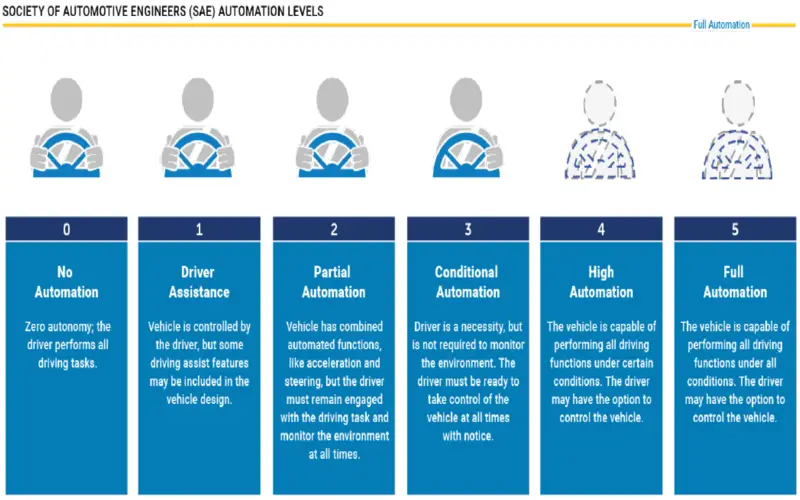

What Are Autonomous Systems?

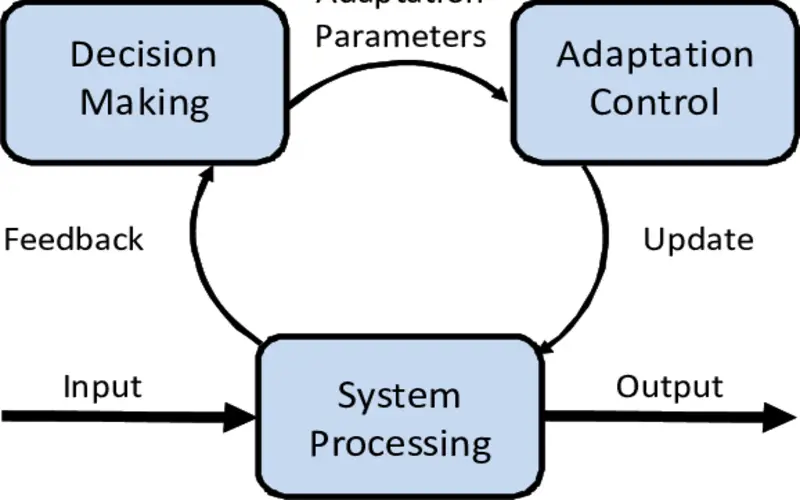

Autonomous Systems, such as self-driving automobiles and some robots, are used without the intervention of humans. An autonomous system can achieve a specific set of goals in an alternate environment, collecting information about the environment and working for an extended period without human intervention or control. For example, driverless cars and autonomous mobile (AMRs) are used in warehouses.

What Do Autonomous Systems Do?

The virtues of robots and other standard autonomous systems are that they expand upon human abilities. Industrial robot systems improve human performance in terms of strength and speed, but their primary advantages in industrial use are correctness and consistency.

Advantages Of Autonomous Systems?

- Minimal human error – Autonomous Systems can reduce mistakes made by people. It is because they are organized to follow particular instructions without variations.

- Maximizes productivity – they can enhance productivity as they work faster and more correctly than humans, thus increasing output.

- Manage in risky environments – these systems can operate in threatening settings where humans might be at risk. They can resist high temperatures, radiation, or toxic chemicals.

- 24/7 – Autonomous Systems can service all day and night without breaks, ensuring continual operational and output.

- Lower operational costs – They can aid in cutting down operational expenditures. They don’t require benefits, vacation time, or sick leave, and they use resources effectively.

1. Lower Costs To Society

Many fully automated systems will lower costs for society due to traffic accidents. The United States could save nearly $800 billion monthly by executing fully automated driving systems. The self-driving cars will minimally fuel costs and proceed. They will also have a positive effect on hospitals and the medical profession.

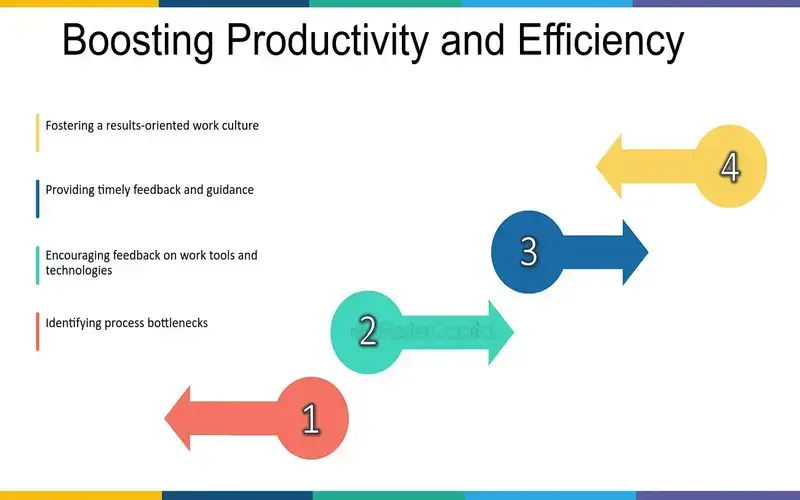

2. Boosted Prolificity And Efficiency

By executing robotic automation and taking benefits of mechanical labor, production can enhance the prolificity and efficiency of their factories. Mechanic robots can work non-stop for 24 hours, abandoned every single day. They can be organized to make exact, immediate movements that are rapid and reliable. This improved production level can help considerably increase the total output of a factory and boost the role of factory employees. When you use Forge/OS to plan your robots, they can be simply initiated for your production lines more effectively, which minimizes cycle lead times and maximizes total efficiency.

3. Improved System Flexibility

Industrial robots are managed to be flexible. With industrial automation, manufacturers can simply retool, redeploy, and reorganize robots for new creation programs and applications. It is beneficial in high-mix, low-volume making environments. Where product needs change often rather than of long product changeover times, robots that are permitted by Forge/OS simple to learn, innate interface, can have rapid changeovers and can quickly switch between distinct products without reading to recreate production lines entirely.

4. Upgraded Product Quality

Human laborers may make occasional issues, and industrial robots are organized to expand particular tasks over again without any loopholes, which results in enhanced product continuously and higher overall quality. By minimizing the likelihood of issues occurring during production, organizing isn’t only enhancing product quality. They also save time and resources that would otherwise be consumed in correcting issues. Manufacturers can benefit from continually high product quality if they correctly service and maintain their industrial robots.

5. Enhanced Safety Measures

Automated robotics use artificial intelligence software that’s outlined to reduce issues. In high-risk work surroundings accidents are essentially reduced when an autonomous robot is doing threatening tasks. These robots can work in conditions that are dangerous for humans. If you are a business owner, you have possibly heard more than enough about the outcomes of workplace injuries. When you have added autonomous robots to your organization, the workplace becomes much safer, reducing risks and adhering to safety standards.

6. Network Security

ASNs can improve network security by making it more difficult for attackers to fake traffic. Having a rare recognition is an extra level of protection from spoofing attacks. ASNs are not economical and need technical skills to set up. The costs vary among listings. The labour costs are not one-off either: ASNs require ongoing access work. The potential benefits could outweigh the costs of ASNs. For example, enhanced security and tracking control plus more effective peering could offset your investment.

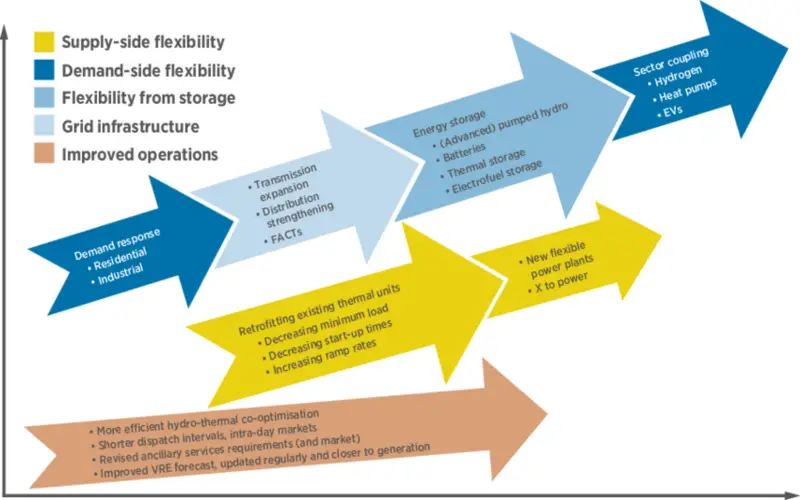

7. Adaptability Autonomous Systems

Designed to respond to changing conditions, these systems advance in dynamic environments. This adaptability is evident in autonomous vehicles navigating through uncertain traffic schemes or robotic systems aligning to variations in manufacturing demands.

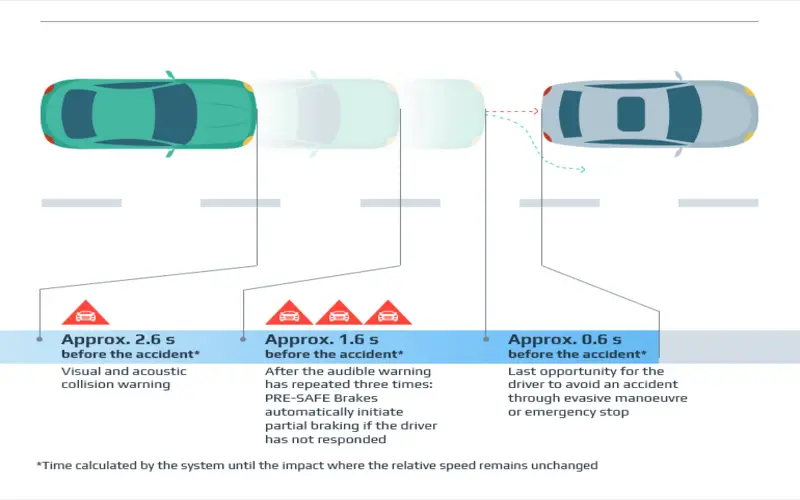

8. Rapid Response Times

It is a vital advantage of autonomous systems, especially in conditions that need quick decision-making. Autonomous vehicles, for example, can recruit emergency braking systems faster than human response, potentially minimizing the intensity of accidents.

9. Autonomous Systems

It is critical in enhancing safety, particularly in dangerous or challenging environments in sections like mining, manufacturing, and results. Where human includes may pose risks, autonomous systems can organize without revealing individuals to danger. It not only secures human lives but also minimizes the likelihood of accidents.

10. Continuous Operation

For human workers who need rest, autonomous systems can function 24/7. This ability is priceless in monitoring, security, and crucial infrastructure observation, where uninterrupted is essential.